Where Steel Moves: The Impact of Motion Solutions on Plant Performance

In the dynamic environment of metal and steel manufacturing ,motion systems are at the heart of nearly every process—from raw material handling and furnace charging to rolling mills ,transfer stations, and automated cranes.

Unlock Uptime with Smart Motion Solutions

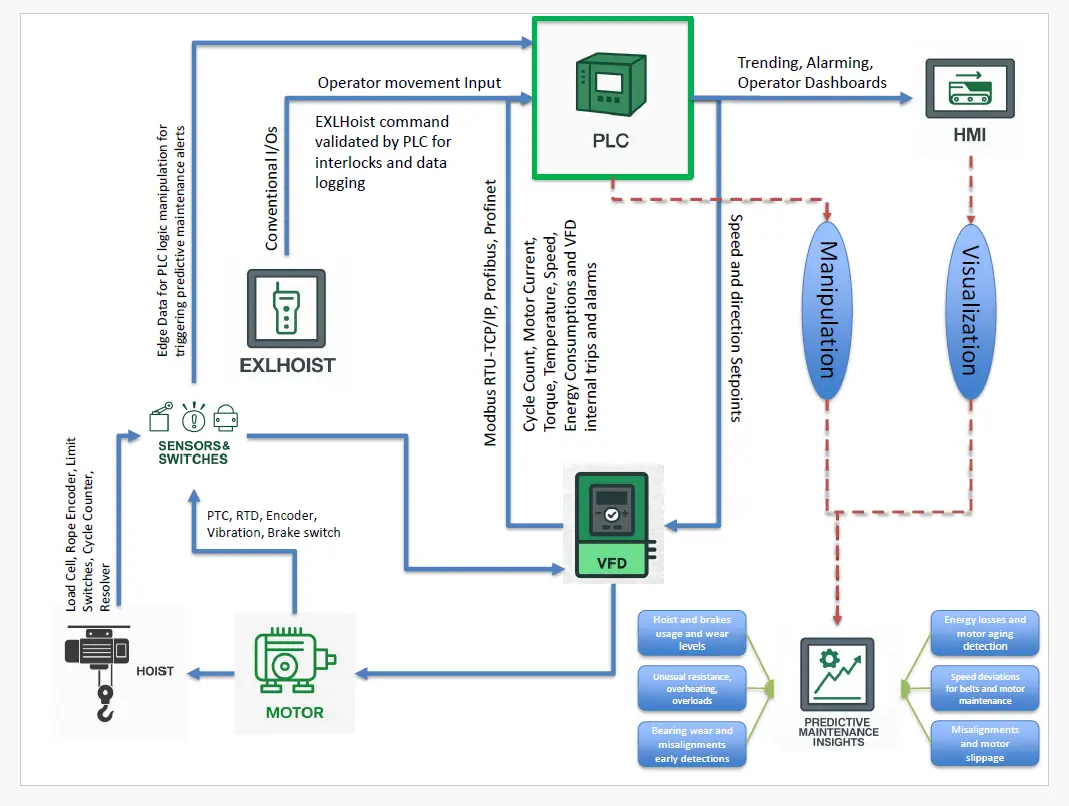

Powered by Schneider Electric technologies, our tailored motion solutions integrate ALTIVAR Variable Frequency Drives, Modicon PLCs, HMIs, and EXLHOIST crane control systems to empower metal and steel manufacturers with real-time diagnostics, condition monitoring, and predictive maintenance insights. This intelligent architecture addresses the leading causes of unplanned downtime—equipment failures and the lack of predictive maintenance—helping reduce downtime by up to 50%. In plants where every hour of lost production can cost tens of thousands of dollars, these solutions drive measurable efficiency and cost savings. With reduced maintenance costs, increased energy efficiency, and improved throughput, most facilities achieve a full Return on Investment (ROI) within 12 to 18 months2, making smart motion systems a high-impact strategic investment.

ALTIVAR Variable Frequency Drives (VFDs) – Engineered for Steel Plant Performance & Precision

Why ALTIVAR stands out

Industrial Real-Time Protocols

Unlike many generic drives, ALTIVAR integrates native dual Ethernet architecture and real-time protocol support (e.g., EtherNet/IP, Modbus TCP, and PROFINET) directly into the drive — eliminating the need for external gateways and ensuring tighter coordination with PLCs and HMIs. This architecture allows real-time data exchange that enables predictive control strategies and system-wide diagnostics.

Smart Thermal & Load Monitoring

ALTIVAR’s embedded thermal sensors and load curve monitoring provide early warning of bearing wear, overload conditions, and mechanical stress — critical in steel plants where equipment runs near maximum capacity.

Embedded Energy Analytics

Its integrated energy efficiency analytics, which benchmark motor performance in real time, help detect inefficiencies caused by misalignments or mechanical degradation — a feature typically reserved for higher-tier systems.

Integrated Safety Functions

Moreover, ALTIVAR drives come with pre-configured safety functions (such as Safe Torque Off and Safe Limited Speed), reducing the need for additional safety relays and simplifying compliance in crane or hoist applications. This built-in intelligence and modularity make ALTIVAR particularly valuable in retrofits and expansions, where minimizing downtime during deployment is vital.

Modicon PLCs – Smart Coordination for Complex Steel Processes

Real-Time Control Meets Predictive Intelligence

Modicon PLCs are designed to orchestrate high-speed, multi-axis operations across steel and metal processing lines — from melt shops to continuous casting and material handling. Their open architecture and native support for industrial Ethernet protocols ensure seamless integration with drives, sensors, and HMIs.

But Modicon goes beyond control:

It acts as the brain of your motion ecosystem — continuously monitoring critical parameters such as torque deviations, motor temperature spikes, abnormal vibration patterns, and cycle time fluctuations. These are among the most telling early indicators of mechanical or electrical faults. Using this data, Modicon PLCs compare real-time values against predictive thresholds. If deviations are detected, they automatically log diagnostics, trigger alerts, and initiate conditional logic to guide maintenance workflows — all without stopping production. This helps maintenance teams act before failure occurs, protecting high-value assets like rolling mill motors, conveyor systems, or crane drives.

The result: fewer breakdowns, improved equipment lifespan, and optimized uptime in even the most complex steel operations.

HMIs – Operational Visibility in Demanding Steel Environments

Operating in noisy, hot, and vibration-heavy zones, steel plant personnel need intuitive, durable interfaces to monitor machine health. Industrial-grade HMIs offer real-time visualization of drive and sensor data across distributed assets — including mill stands, crane systems, and hydraulic presses. When linked with Modicon PLCs and ALTIVAR VFDs, HMIs alert operators to predictive trends like heat build-up in bearings or drift in motor loads. This centralized visibility empowers maintenance crews to intervene proactively, reducing the risk of cascading failures and production bottlenecks.

EXLHoist – Safer, Smarter Lifting for Overhead Crane Operations

Heavy-duty hoisting is a cornerstone of material handling in steel plants — from charging furnaces with raw materials to transporting massive steel coils. EXLHoist is purpose-built for high-load, high-cycle crane operations, delivering smoother acceleration, sway reduction, and controlled braking to minimize mechanical stress on hoist components. Its integrated diagnostics — including cycle counting, overload detection, and brake wear tracking — feed actionable data into PLCs and HMIs, supporting predictive maintenance strategies. This reduces the risk of unexpected hoist failures, extends asset lifespan, and improves safety in the plant’s most demanding environments.